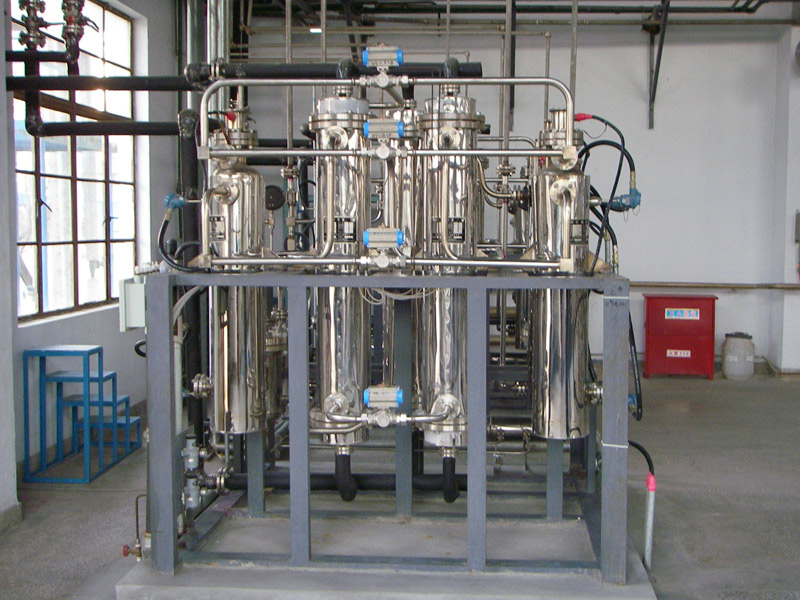

Gas Purification System

PSA hydrogen rich tail gas purification hydrogen series equipment

Various hydrogen rich tail gases such as chlor alkali plant tail gas, coke oven gas, water gas, city gas, refinery catalytic cracking dry gas, reforming tail gas, shift gas, coal chemical industry decomposition ammonia, decomposition methanol release gas, fermentation gas, etc. are pressurized and pretreated according to actual conditions to remove impurities that are not suitable for pressure swing adsorption treatment. After purification by pressure swing adsorption, the product hydrogen gas is output.

Technical features:

1. Design a reasonable production process structure based on actual working conditions to reduce operating costs.

2. Select high-quality programmable valves with high reliability.

3. High degree of automation, unmanned operation.

4. Reliable security design ensures safe operation and running.

5. The device has high integration and is exquisite and beautiful.

1. Propane dehydrogenation tail gas purification hydrogen device: Various hydrogen rich tail gases such as propane dehydrogenation tail gas are pressurized and pretreated according to the actual situation to remove impurities that are not suitable for pressure swing adsorption treatment. After purification by pressure swing adsorption, the product hydrogen is output.

2. Polycrystalline silicon tail gas purification hydrogen device: The tail gas produced by polycrystalline silicon contains hydrogen, hydrogen chloride, trichlorosilane, silicon tetrachloride, dichlorosilane and other components. After pressurization, each component can be separated and purified through single-stage or multi-stage pressure swing adsorption to achieve the purpose of recycling.

3. Synthetic ammonia venting gas purification hydrogen device: Various hydrogen rich exhaust gases such as synthetic ammonia and urea venting gases are pressurized and pretreated according to actual conditions to remove impurities that are not suitable for pressure swing adsorption treatment. After purification by pressure swing adsorption, the product hydrogen gas is output.

4. Hydrogen purification device for coke oven gas: After being pressurized by a coal press, coke oven gas is subjected to a pre-treatment tower to remove tar and hydrogen sulfide, and then enters a temperature swing adsorption tower mixed with various adsorbents to remove impurities such as water and naphthalene. After being purified by pressure swing adsorption, the hydrogen gas is further removed from residual oxygen by palladium catalyst and moisture by a drying tower, and the product hydrogen gas is output. The heat source used for temperature swing adsorption comes from steam, the regenerated gas used comes from pressure swing adsorption desorption gas, and the regenerated tail gas enters the gas pipeline network.

5. Chlor alkali tail gas purification hydrogen device: The hydrogen rich chlor alkali tail gas from the chlor alkali plant is compressed and pressurized, and then enters the deoxygenation tower equipped with palladium catalyst to remove oxygen. Then, it is subjected to pressure swing adsorption to remove impurities such as N2, CO, CO2, Cl, H2O, and output product hydrogen gas.

Related Products:

Hit:464 Enter time:2025-05-12 11:33:40【Return】