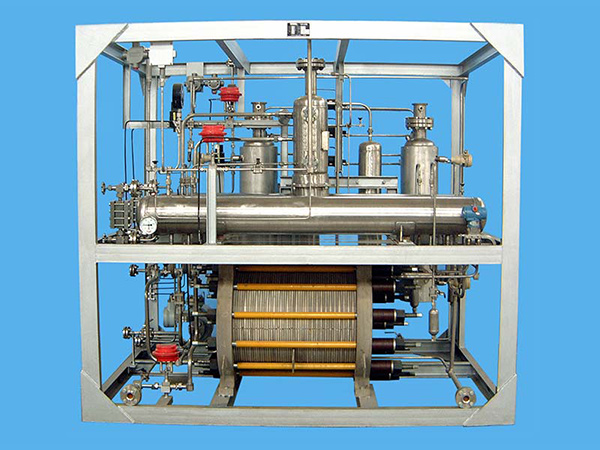

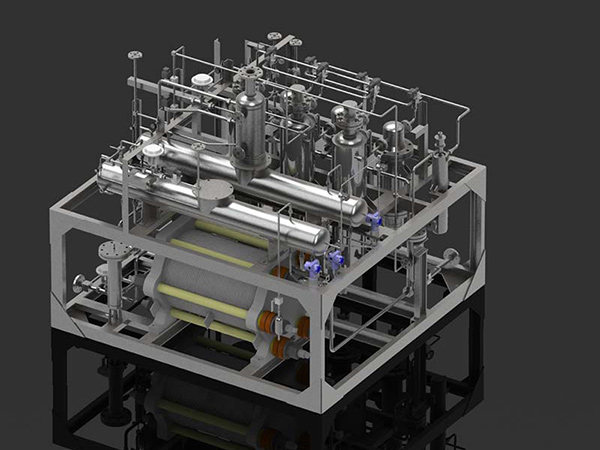

Integrated-type H2 generator

As one of the most compact products, the integrated-type hydrogen generator is specially designed for electrical power industry. Ranging from 5Nm³/h to 15Nm³/h and operating pressure 1.50MPa(g), the hydrogen flow from the single hydrogen generator integrated electrolyzer, gas-lye treater and H2 purification unit in one skid; the H2 purity is better than 99.999% and dew point better than -60 Deg.C. With this integration, the hydrogen generator becomes more convenient to customers for installation, operation and maintenance, also saving the capital cost on the civil construction. Full automatic control is realized without interfering by the customer and is available to be connected with customer’s DCS system for monitoring.

After rapid development in recent years, we have established a comprehensive after-sales service team consisting of nearly 40 senior engineers, covering civil engineering, installation, commissioning, training and other services.

Our after-sales service team guarantees that each set of equipment can be quickly delivered to the customer with the best performance during on-site installation and commissioning. At the same time, after the equipment is officially put into production, we also provide professional online technical Q&A and fast on-site service in case of equipment failure.

PERIC has always been adhering to the principle of customer first, and has established long-term cooperation and service relationship with domestic and foreign customers. We also hold training courses and lectures for domestic and foreign customers together with China Industrial Gases Industry Association Hydrogen Professional Committee. The class has adopted various training methods including technical analysis, case explanation, exchange seminars etc. So far, 40 sessions have been held, and unanimously recognized and praised by users at home and abroad.

Why Choose us

state-owned company with integrated capabilities in R&D, design and manufacture, and service of H2 generation.

HONORS

PERIC has been awarded with the National Prize for Progress in Science and Technology for more than 20 times, and our hydrogen generation plant by water electrolysis was listed in National Torch Plan Projects.

TECHNOLOGY

China’s ONLY national research institute specialized in hydrogen generation by water electrolysis and world's largest manufacturing base for alkaline and PEM water electrolysis as per hydrogen generation

PERSONNEL

PERIC has total more than 2,000 employees, including 870 scientists and engineers, amongst 30 experts are awarded National Specialists, 84 are entitled Senior Scientists, and 420 hold PhD or Master degrees.